Vinyl acetate (Vac), oo sidoo kale loo yaqaano vinyl acetate ama vinyl acetate, waa dareere aan midab lahayn oo hufan heerkulka caadiga ah iyo cadaadiska, oo leh qaacido kelli ah oo ah C4H6O2 iyo miisaanka unugga qaraabada ah ee 86.9.Vac, oo ah mid ka mid ah alaabta ceeriin ee dabiiciga ah ee aadka loo isticmaalo ee warshadaha adduunka, waxay dhalin kartaa soosaarayaal sida polyvinyl acetate resin (PVAc), alkolada polyvinyl (PVA), iyo polyacrylonitrile (PAN) iyada oo loo marayo is-polymerization ama isku-duubnida monomers kale.Alaabooyinkan ayaa si weyn loogu isticmaalaa dhismaha, dunta, mishiinada, daawada, iyo hagaajinta carrada.Sababtoo ah horumarinta degdega ah ee warshadaha terminalka sannadihii la soo dhaafay, wax soo saarka vinyl acetate ayaa muujisay isbeddel sii kordhaya sanadba sanadka ka dambeeya, iyada oo wadarta guud ee wax soo saarka vinyl acetate ay gaartay 1970kt ee 2018. Hadda, sababtoo ah saameynta alaabta ceeriin iyo hababka wax soo saarka ee vinyl acetate inta badan waxaa ka mid ah habka acetylene iyo habka ethylene.

1. Habka acetylene

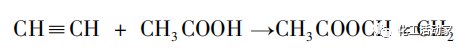

Sannadkii 1912-kii, F. Klatte, Canadian ah, ayaa markii ugu horreysay helay vinyl acetate iyadoo la isticmaalayo acetylene iyo acetic acid oo ka hooseysa cadaadiska atmospheric, heerkul u dhexeeya 60 ilaa 100 ℃, iyo isticmaalka cusbada meerkuriga sida kicinta.Sannadkii 1921kii, Shirkadda Jarmalka ee CEI waxay soo saartay tignoolajiyad loogu talagalay isku-darka wajiga uumiga ee vinyl acetate ee acetylene iyo acetic acid.Tan iyo markaas, cilmi-baarayaal ka kala yimid dalal kala duwan ayaa si joogto ah u hagaajiyay habka iyo xaaladaha loogu talagalay isku-dhafka vinyl acetate ee acetylene.Sannadkii 1928, Shirkadda Hoechst ee Jarmalka waxay aasaastay 12 kt/a unugga wax-soo-saarka vinyl acetate, iyada oo xaqiiqsatay wax-soo-saarka baaxadda weyn ee vinyl acetate.Isla'egta soo saarista vinyl acetate ee habka acetylene waa sida soo socota:

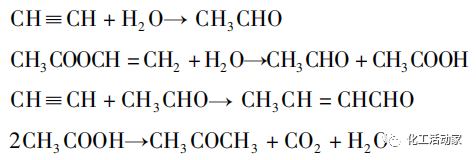

Falcelinta ugu weyn:

Habka acetylene waxa loo qaybiyaa habka wajiga dareeraha ah iyo habka wajiga gaaska.

Xaaladda wajiga falcelinta ee habka dareeraha acetylene waa dareere, reactor-kuna waa haan falcelin leh oo leh qalab wax kicinaya.Sababo la xiriira cilladaha habka wejiga dareeraha sida xulashada hooseeya iyo alaabooyin badan, habkan waxaa lagu beddelay habka wajiga gaaska acetylene hadda.

Sida laga soo xigtay ilaha kala duwan ee diyaarinta gaaska acetylene, habka wajiga gaaska acetylene waxa loo qaybin karaa habka gaaska dabiiciga ah acetylene Borden iyo habka carbide acetylene Wacker.

Habka Borden wuxuu isticmaalaa acetic acid sida adsorbent, kaas oo si weyn u wanaajinaya heerka isticmaalka acetylene.Si kastaba ha noqotee, dariiqa geeddi-socodkani waa farsamo ahaan adag wuxuuna u baahan yahay kharashyo badan, markaa habkani wuxuu faa'iido u leeyahay meelaha qani ku ah kheyraadka dabiiciga ah.

Habka Wacker wuxuu isticmaalaa acetylene iyo acetic acid laga soo saaro calcium carbide sida alaabta ceeriin, iyadoo la isticmaalayo kicinta leh kaarboon firfircoon sida side iyo zinc acetate oo ah qayb firfircoon, si loo soo saaro Vac ee cadaadiska atmospheric iyo heerkulka falcelinta ee 170 ~ 230 ℃.Tiknoolajiyada geeddi-socodka waa mid fudud oo leh kharash yar oo wax soo saar ah, laakiin waxaa jira cillado sida luminta fudud ee qaybaha firfircoon ee kicinta, xasiloonida liidata, isticmaalka tamarta sare, iyo wasakhowga weyn.

2. Habka Ethylene

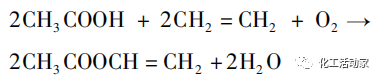

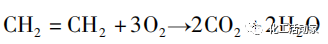

Ethylene, oksijiin, iyo glacial acetic acid waa saddex walxood oo ceeriin ah oo loo isticmaalo isku dhafka ethylene ee geeddi-socodka vinyl acetate.Qaybta ugu muhiimsan ee firfircoon ee kicinta waa sida caadiga ah kooxda sideedaad ee birta sharafta leh, taas oo ka falcelisa heerkul falcelin gaar ah iyo cadaadis.Ka dib habaynta soo socota, badeecada bartilmaameedka ah ee vinyl acetate ayaa ugu dambeyntii la helay.Isla'egta falcelintu waa sida soo socota:

Falcelinta ugu weyn:

Waxyeellooyinka soo raaca:

Habka wejiga uumiga ethylene waxaa markii ugu horreysay soo saartay Bayer Corporation waxaana lagu dhejiyay wax soo saarka warshadaha si loo soo saaro vinyl acetate 1968. Khadadka wax soo saarka ayaa lagu aasaasay Hearst iyo Bayer Corporation ee Jarmalka iyo National Distillers Corporation ee Maraykanka, siday u kala horreeyaan.Inta badan waa palladium ama dahab ku raran taageerooyinka u adkaysta aashitada, sida kuul silica jel oo leh radius of 4-5mm, iyo ku darida xaddi go'an oo ah potassium acetate, taas oo hagaajin karta dhaqdhaqaaqa iyo xulashada kicinta.Habka loogu talagalay isku-dhafka vinyl acetate iyadoo la adeegsanayo wajiga ethylene uumiga USI habka wuxuu la mid yahay habka Bayer, waxaana loo qaybiyaa laba qaybood: isku-dhafka iyo kala-baxa.Nidaamka USI wuxuu gaadhay codsiga warshadaha 1969. Qaybaha firfircoon ee kicinta ayaa inta badan ah palladium iyo platinum, iyo wakiilka kaaliyaha waa potassium acetate, kaas oo lagu taageerayo alumina side.Xaaladaha falcelintu waa kuwo khafiif ah, kiciniyuhuna waxa uu leeyahay nolol adeeg oo dheer, laakiin wax-soo-saarka-waqtiga-booska ayaa hooseeya.Marka la barbardhigo habka acetylene, habka wejiga uumiga ethylene ayaa si weyn u fiicnaaday tignoolajiyada, iyo kicinta loo isticmaalo habka ethylene ayaa si joogto ah u wanaajiyey dhaqdhaqaaqa iyo xulashada.Si kastaba ha ahaatee, dhaqdhaqaaqa falcelinta iyo habka deminta ayaa weli u baahan in la sahamiyo.

Soo saarista vinyl acetate iyadoo la adeegsanayo habka ethylene waxay isticmaashaa dab-dhaliye go'an oo tuubo ah oo ay ka buuxaan kicin.Gaaska quudinta ayaa ka soo gasha reactor-ka xagga sare, iyo marka ay la xiriirto sariirta kicinta, fal-celinta catalytic waxay dhacdaa si ay u abuurto badeecada bartilmaameedka ah ee vinyl acetate iyo qadar yar oo ka mid ah alaabta kaarboon laba ogsaydh.Dabeecadda falcelinta kacsiga awgeed, biyaha la cadaadiyo ayaa lagu soo geliyaa dhinaca qolofka reactor-ka si looga saaro kulaylka falcelinta iyadoo la isticmaalayo uumiga biyaha.

Marka la barbardhigo habka acetylene, habka ethylene wuxuu leeyahay sifooyin qaabdhismeedka qalabka is haysta, wax soo saarka weyn, isticmaalka tamarta yar, iyo wasakhowga hooseeya, qiimaha alaabtiisuna wuu ka hooseeyaa habka acetylene.Tayada alaabadu way ka sareysaa, xaalada daxalkana maaha mid halis ah.Sidaa darteed, habka ethylene wuxuu si tartiib tartiib ah u beddelay habka acetylene ka dib 1970-yadii.Marka loo eego tirakoobka aan dhameystirneyn, qiyaastii 70% Vac ee ay soo saartay habka ethylene adduunka ayaa noqday habka ugu muhiimsan ee hababka wax soo saarka Vac.

Waqtigan xaadirka ah, tignoolajiyada wax soo saarka Vac ee adduunka ugu horumarsan waa Habka Leap ee BP iyo Nidaamka Vantage ee Celanese.Marka la barbar dhigo geeddi-socodka wejiga gaaska go'an ee dhaqanka ee ethylene, labadan tignoolajiyada geeddi-socodku waxay si weyn u wanaajiyeen reactor-ka iyo kicinta xudunta unugga, hagaajinta dhaqaalaha iyo badbaadada hawlgalka unugga.

Celanese waxay soo saartay hab cusub oo sariir go'an oo Vantage ah si wax looga qabto dhibaatooyinka qaybinta sariiraha ee aan sinnayn iyo beddelka ethylene oo hooseeya ee hal-jidka reactors go'an.Reactor-ka loo isticmaalo geeddi-socodkan ayaa weli ah sariir go'an, laakiin horumar weyn ayaa lagu sameeyay nidaamka kicinta, iyo qalabka soo kabashada ethylene ayaa lagu daray gaaska dabada, isaga oo ka gudbaya cilladaha hababka sariiraha go'an ee dhaqameed.Wax-soo-saarka badeecada vinyl acetate aad ayuu uga sarreeyaa qalabka la midka ah.Kaaliyaha geeddi-socodku wuxuu isticmaalaa platinum oo ah qaybta ugu muhiimsan ee firfircoon, silica jel oo ah side kicinta, sodium citrate oo ah wakiilka yaraynta, iyo biraha kale ee caawiya sida lanthanide curiyeyaasha dhulka naadirka ah sida praseodymium iyo neodymium.Marka la barbar dhigo kicinta dhaqameed, xulashada, waxqabadka, iyo wax-soosaarka wakhtiga-meel-gaadhka ah ee kicinta waa la wanaajiyey.

BP Amoco waxay soo saartay hab socodka gaaska ethylene sariirta dareere leh, sidoo kale loo yaqaan habka Leap Process, waxayna ka dhistay 250 kt/ unug sariireed dareere ah gudaha Hull, England.Isticmaalka habkan si loo soo saaro vinyl acetate waxay hoos u dhigi kartaa qiimaha wax soo saarka 30%, iyo wax-soo-saarka wakhtiga booska ee kicinta (1858-2744 g / (L · h-1)) aad ayuu uga sarreeyaa habka sariirta go'an (700). -1200 g/ (L · h-1)).

Habka LeapProcess waxa uu isticmaalaa reactor-ka sariirta dareeraha leh markii ugu horeysay, kaas oo leh faa'iidooyinka soo socda marka la barbar dhigo reactor go'an:

1) Dareeraha sariiraha dareeraha leh, kicinta ayaa si joogto ah oo isku mid ah isku dhafan, taas oo ka qayb qaadanaysa faafinta lebiska ee dhiirrigeliyaha iyo hubinta isku-darka dhiirrigeliyaha ee reactor-ka.

2) Dareemiyaha sariiraha dareeraha leh ayaa si joogto ah ugu bedeli kara kicinta demasay ee katalyaha cusub ee xaaladaha hawlgalka.

3) Heerkulka falcelinta sariirta ee dareeraha ah waa mid joogto ah, oo yaraynaysa deactivation kisiyaha sababtoo ah kulaylka deegaanka, taas oo kordhinaysa nolosha adeegga kicinta.

4) Habka ka saarista kulaylka ee loo isticmaalo reactor-ka sariiraha dareeraha leh ayaa fududeynaya qaab-dhismeedka reactor wuxuuna yareeyaa mugga.Si kale haddii loo dhigo, hal nakhshad hal-abuure ah ayaa loo isticmaali karaa rakibaadyo kiimiko oo baaxad leh, taasoo si weyn u wanaajinaysa waxtarka miisaanka aaladda.

Waqtiga boostada: Mar-17-2023